B21, China Town Mall, Midrand

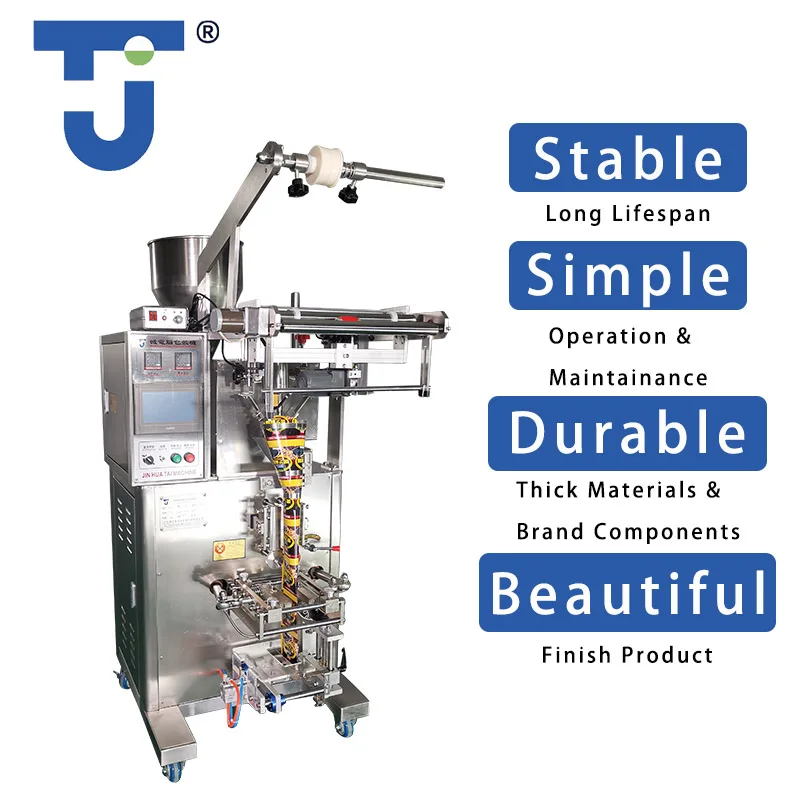

5g White Sugar Packet Solid Drink Ginger Granule Pouch Sachet Full Automatic Vertical Packing Multi-Function Packaging Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1601027426946

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What products can this machine pack?

The machine is designed for fine granular materials such as white sugar, seeds, beans, chemical fertilizers, and similar granules used in food, chemical, pharmaceutical and daily-use industries.

2. Can it make 5 g white sugar sachets (small pouch) as the product name suggests?

Yes. The DF-50AYB swing filling machine supports a filling range of 5–100 g and bag sizes L: 50–200 mm and W: 20–110 mm, making it suitable for 5 g white sugar sachets.

3. What is the packing speed (output) of the machine?

Typical packing speed is 30–50 bags per minute, depending on product properties, bag size and film material.

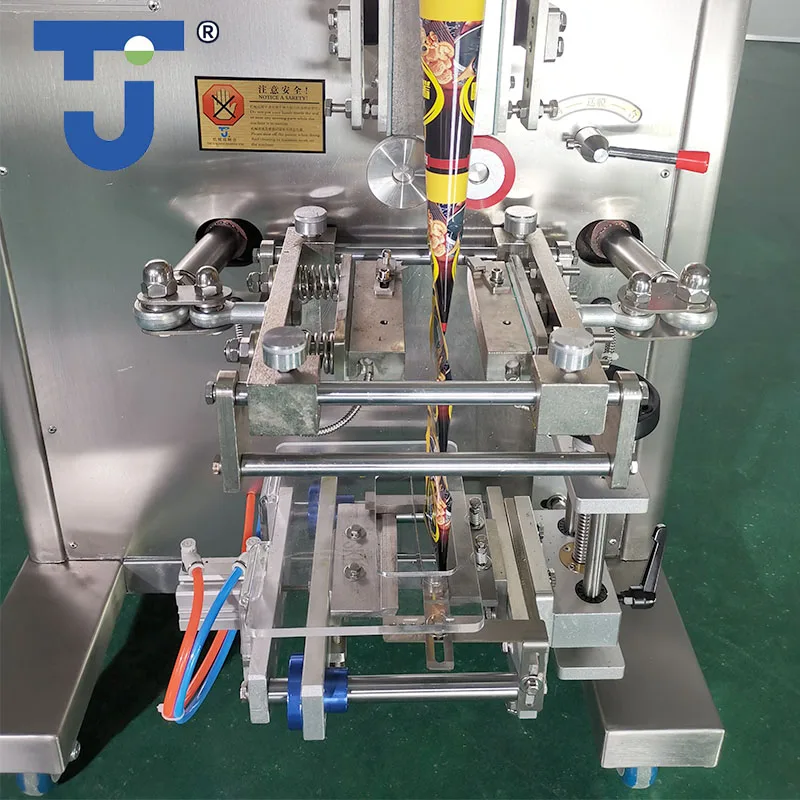

4. What filling system and sealing type does the machine use?

It uses a mechanical swing filler system for accurate dosing and a three-side sealing configuration for sachets/pouches.

5. What film materials and bag types are supported?

Supports roll film sachets/pouches made from composite and common packaging films such as AL (metal), paper, OPP/CPP, PET/PE, PA and EVOH composites.

6. What are the machine's main specifications (power, weight, dimensions)?

Voltage: 220V 50/60Hz; Total power: 2.5 kW; Weight: ~350 kg; Machine body: stainless steel SUS 304; Dimensions (L×W×H): approximately 1000 × 900 × 2000 mm.

7. How precise is the filling / what is the weight accuracy?

The swing filling system is designed for small weight deviations and precise dosing. Exact accuracy depends on material flowability, bag size and calibration; we recommend product testing for a guaranteed tolerance range.

8. How easy is it to change bag sizes or adjust weight?

Weight adjustment is simple and does not require changing measuring cups. The servo motor bag pulling system allows precise, easy adjustment of bag length and positioning.

9. What materials is the machine constructed from and is it suitable for food use?

The machine body and contact parts are made from stainless steel SUS 304, providing durability and hygienic properties suitable for many food applications.

10. How much product loss/waste should I expect?

The swing filling design minimizes material loss compared with less-precise fillers. Actual loss depends on product characteristics and operational settings; proper setup and operator training further reduce waste.

11. Is installation, commissioning and operator training provided?

Installation, commissioning and operator training can be provided—please contact sales to arrange details and any associated costs.

12. Are spare parts and after-sales support available?

Yes. Spare parts and after-sales service are available. Contact our service team for parts lists, lead times and service agreements.

13. Can the electrical configuration or voltage be customized for my location?

Yes, the standard unit is specified as 220V 50/60Hz. Other voltages or electrical configurations can typically be supplied on request—please discuss requirements with sales.

14. How do I get pricing, lead time or place an order?

For price quotes, lead times, customization options or to place an order, please contact our sales department with your product details (material, target bag size, speed requirement) so we can provide an accurate proposal.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading