B21, China Town Mall, Midrand

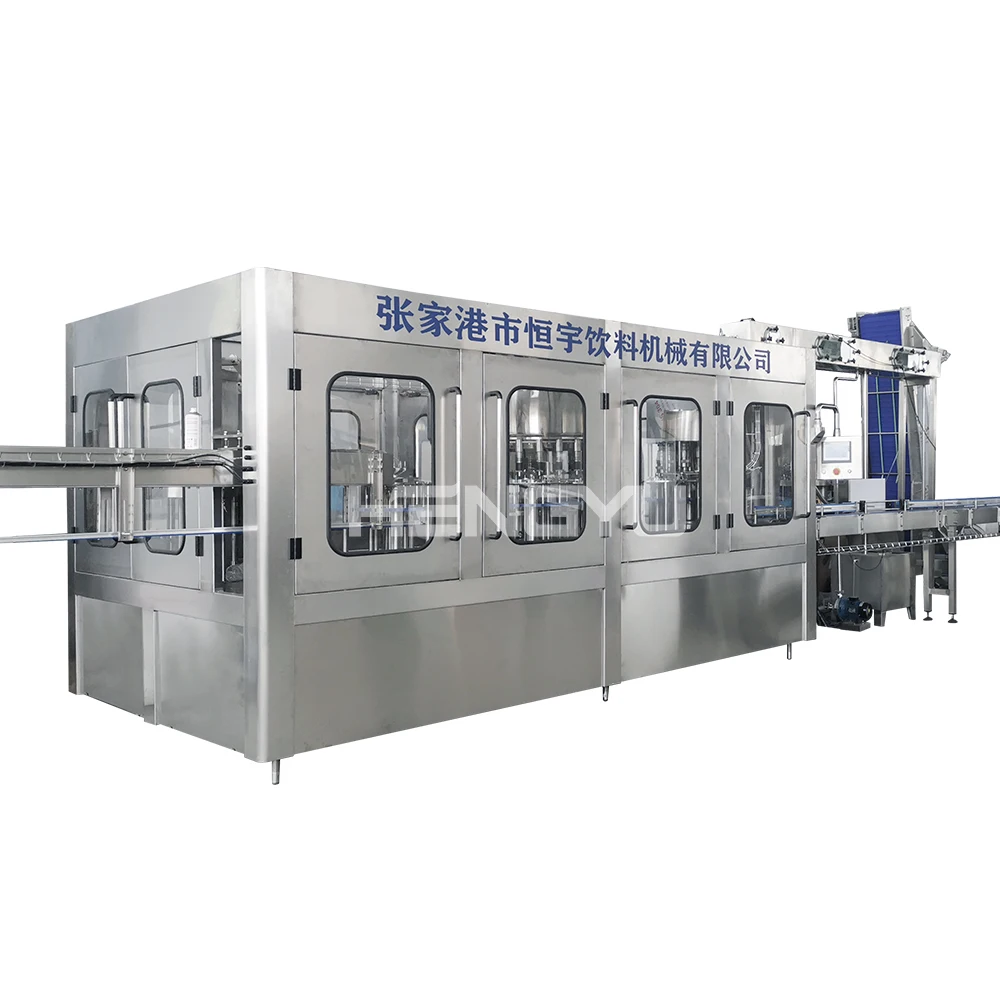

3-in-1 Automatic Water Bottling Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 62351861266-1724156352

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 16 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of beverages can the 3-in-1 Automatic Water Bottling Machine handle?

The machine is designed to handle a variety of beverages, including mineral water, soft drinks, and carbonated beverages.

2. What is the production capacity of the machine?

The 3-in-1 Automatic Water Bottling Machine has a production capacity of 12,000 bottles per hour (BPH) at 500ml.

3. What materials are used in the construction of the machine?

The machine is built with SUS304 stainless steel, ensuring durability and resistance to corrosion.

4. How does the machine achieve high filling accuracy?

It utilizes advanced filling technology that achieves 99.9% precision, minimizing waste and ensuring consistent quality.

5. Is the machine energy-efficient?

Yes, the machine is optimized for energy-saving performance, which reduces operational costs while maintaining high output.

6. What type of control system does the machine use?

The machine features an advanced PLC system and international-standard electrical components for smooth, user-friendly operation.

7. Can the machine be customized to fit my production line?

Yes, the 3-in-1 Automatic Water Bottling Machine has OEM dimensions that allow it to fit seamlessly into your production line layout.

8. What safety features are included in the machine?

The machine includes a cover missing and overload protection alarm device to identify and eliminate faults in a timely manner.

9. How does the rinsing process work?

The machine uses a new generation of stainless steel flip bottle clamps, which allow full rinsing of the bottle's inner wall without dead corners.

10. What is the advantage of using a magnetic torque type capping head?

The magnetic torque type capping head allows for infinitely adjustable capping torque, ensuring tight and reliable sealing without damaging the cap.

11. Is the machine easy to operate?

Yes, it features a man-machine interface with touch screen buttons for easy operation and high automation.

12. What should I do if I encounter a problem with the machine?

The machine is equipped with an alarm system that helps identify issues, and you can refer to the user manual for troubleshooting guidance.

13. What are the technical parameters of the machine?

The machine comes in various models with different specifications for rinsing, filling, and capping heads, as well as power and dimensions. Please refer to the product details for specific model parameters.

14. Can the machine handle different bottle sizes?

Yes, the design allows for convenient and fast changes between different bottle types, minimizing the number of changed parts.

15. How does the machine's filling mechanism work?

The machine adopts an advanced gravity filling principle, which ensures fast, stable, and accurate filling of the beverages.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading