B21, China Town Mall, Midrand

30CM All in One UV DTF Printer Laminator Sticker Roll A3 Label Sticker Printing Machine

- Section : Consumer Electronics

- Category : DTF Printers

- SKU : 1600881629257

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 15 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the 30CM All in One UV DTF Printer Laminator Sticker Roll A3 used for?

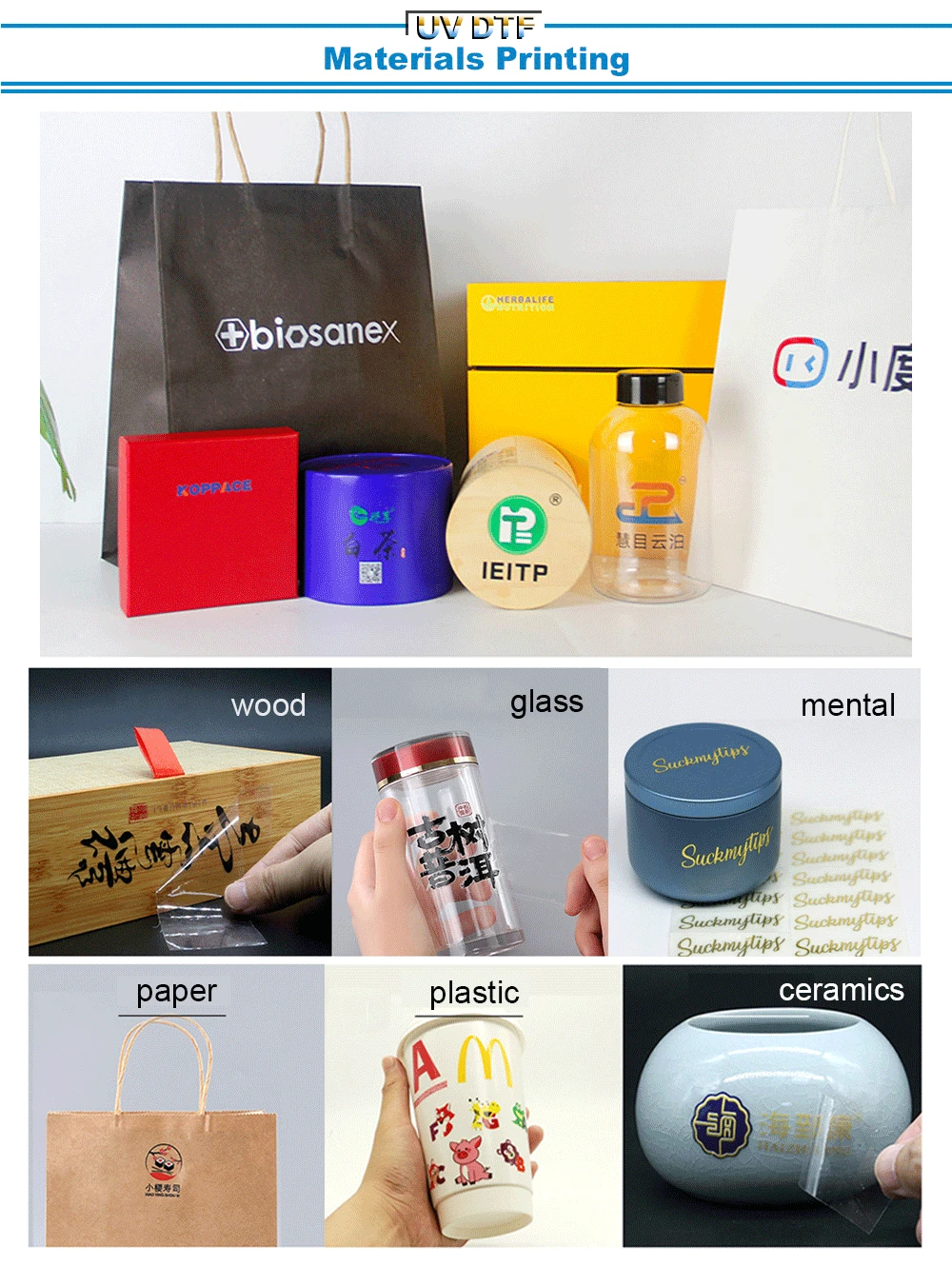

It's an all-in-one roll-to-roll UV DTF printer with an integrated laminator designed for producing high-quality labels, stickers, decals and DTF transfers for items like phone cases, bottles, wood, glass and other materials up to A3/300 mm wide.

2. What is the maximum print width and print area?

The standard model prints up to 300 mm (30 cm / A3 width). Some configurations or models may also be available in a 600 mm width — check the specific SKU before purchasing.

3. Which printheads does this machine use?

The machine ships with Epson-style XP600 printheads (configurations with TX800 may be available). It uses 2–3 printheads depending on the model/option to achieve high throughput and precision.

4. What inks and colors are supported?

It uses UV-curable DTF inks in CMYK + White + Varnish. The UV inks cure for durable, scratch- and fade-resistant prints; white ink and varnish channels are available for opacity and spot gloss/matte finishing.

5. What is the maximum print resolution and typical print speed?

Maximum resolution is up to 1440 DPI. Speed depends on pass mode and media: typical throughput varies by setting (examples include 6-pass and 8-pass modes). In practice you can expect a range (e.g., ~1–5 m²/h depending on pass mode, RIP settings and media).

6. Does the machine include an integrated laminator?

Yes — it includes an integrated laminating unit so printed rolls can be laminated inline for immediate finishing and improved durability.

7. What materials and substrates can it print on?

It's designed for AB UV DTF film (roll-to-roll) and is suitable for transfers to many surfaces including textiles, plastic, metal, glass, wood, bottles, cards and other irregular items when used with the correct film and transfer process. Direct printing on rigid/irregular objects may require fixtures or optional accessories.

8. How does the roll-to-roll workflow work?

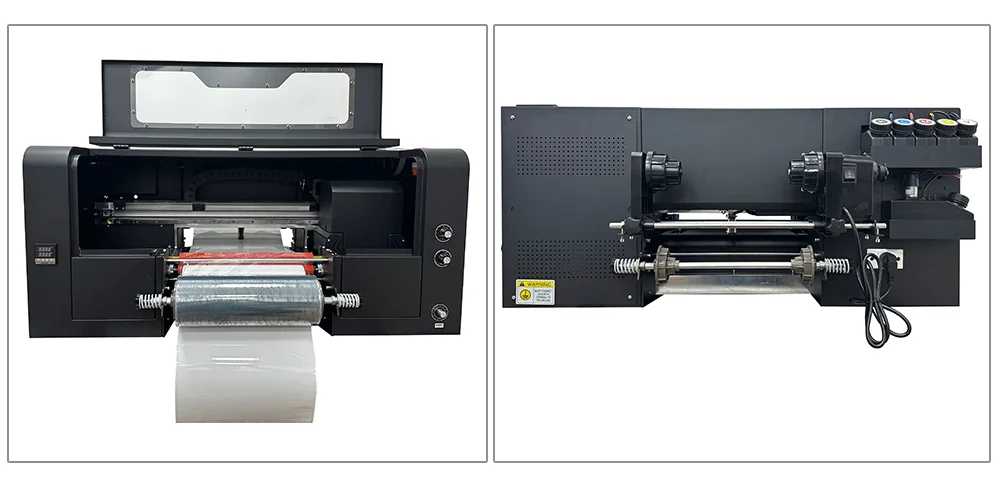

Load the DTF film roll on the unwinder, print with the integrated UV system, then the output goes through the integrated laminator and is rewound — allowing continuous, high-volume sticker and label production without manual handling between steps.

9. What RIP/software does the printer support?

The product is compatible with common RIPs; listed software includes Maintop 6.1 and PhotoPrint. The RIP is required to manage white and varnish channels, color separation and print queues. It also accepts standard image formats (TIFF/JPG/PDF/PSD/AI) via RIP.

10. What connectivity options are available?

Primary data transfer is via Gigabit Ethernet for stable, high-speed file transfer. Some vendors may also provide USB or other options depending on configuration.

11. What consumables and maintenance items will I need?

Consumables include UV DTF inks (CMYK+White+Varnish), AB DTF film rolls, cleaning solution, maintenance kits (capping station, wipers), replacement dampers and potentially replacement printheads over the long term. White ink circulation and CISS maintenance are important for reliability.

12. Does the printer have a continuous ink supply system (CISS)?

Yes — it features a continuous ink supply system to support long uninterrupted runs, reduce refill frequency and lower operating costs. Proper setup and periodic maintenance of the CISS and white-ink circulation are important.

13. What are the power and environmental requirements?

The unit supports AC110V or AC220V (50/60 Hz) depending on configuration. Recommended operating environment: temperature 20°C–35°C and relative humidity 35%–65% RH for optimal print quality and ink stability.

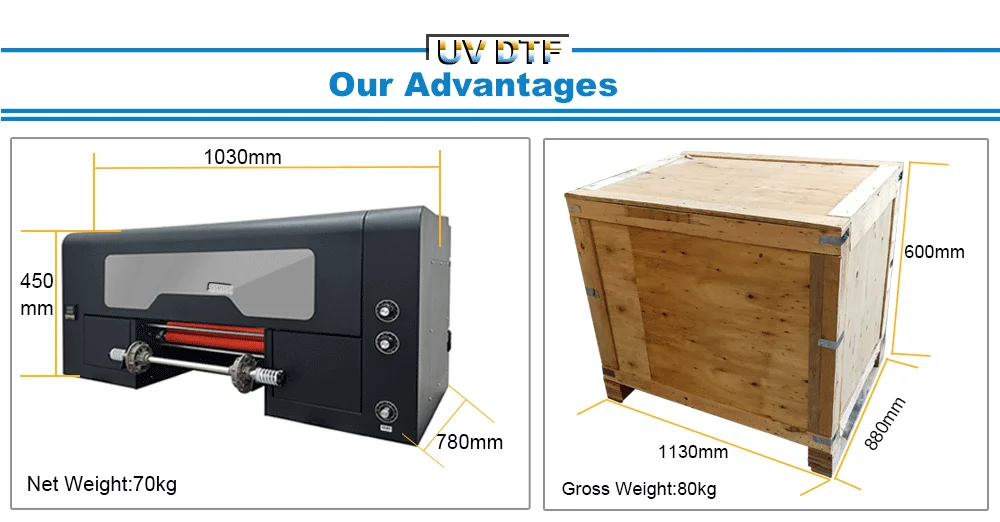

14. What are the printer dimensions, weight and warranty?

Printer dimensions are approximately 1030 × 780 × 450 mm (L × W × H); packed dimensions ~1130 × 880 × 600 mm. Net weight is about 70 kg and gross weight about 80 kg. The product includes a 1-year warranty; check the seller for warranty scope and local support details.

15. What routine maintenance is required to keep the printer running reliably?

Perform daily or regular printhead checks and nozzle tests, use the built-in cleaning/capping routines, circulate and purge white ink as recommended, keep the capping station and wipers clean, replace consumables per schedule, and follow the user manual for periodic deeper maintenance. Regularly update RIP settings and firmware as provided by the supplier.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading

>

>