B21, China Town Mall, Midrand

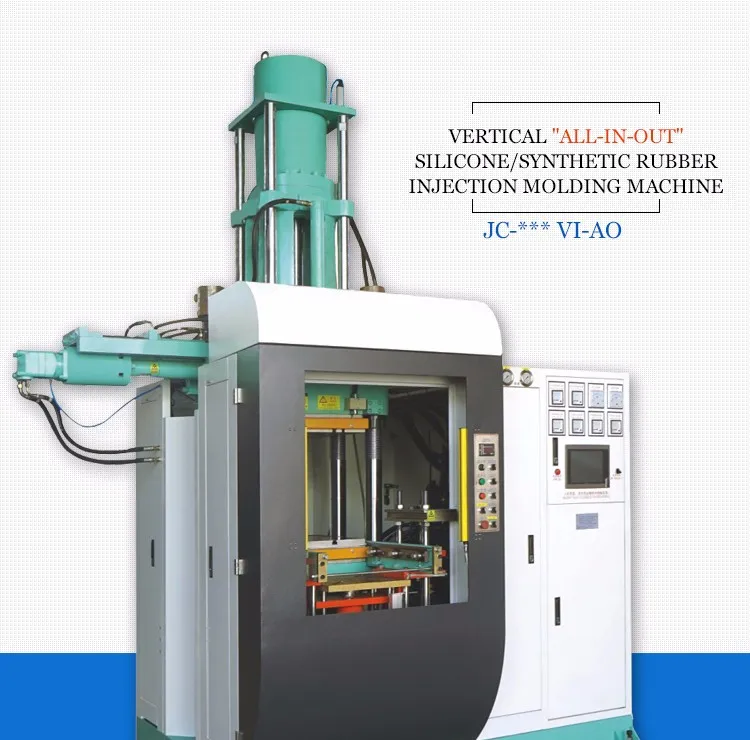

300 Ton For Rubber Shoe Sole Making Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600899508020

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 08 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the 300 Ton For Rubber Shoe Sole Making Machine?

The 300 Ton is the VI-AO series vertical "all-in-out" silicone/synthetic rubber injection molding machine designed for high-precision rubber parts such as shoe soles. It features sprueless (all-in-out) injection, servo-driven control for energy savings, and an anti-collision molding system.

2. What are the main specifications of the 300 Ton model (300VI-AO)?

Key specs for the 300VI-AO: clamping force 300 Ton; injection capacity ~3000 cc; injection pressure 1800 kgf/cm²; operation table size 700 × 700 mm; minimum mold thickness 100 mm; plunger stroke 400 mm; thermo-plate distance 500–600 mm; tie-bar distance 820 × 395 mm; maximum operating pressure 20 MPa; motor power 15 hp.

3. Which materials can this machine process?

It is suitable for silicone and synthetic rubbers, including NBR (nitrile butadiene rubber). It is also appropriate for a wide range of automotive, electronic, and high-/low-temperature precision rubber parts.

4. Is this machine suitable for making rubber shoe soles?

Yes. The 300 Ton model is specifically suitable for shoe sole production thanks to its large clamping force, sprueless all-in-out system (reducing material waste), high injection capacity, and high-precision control.

5. What does 'all-in-out' or 'sprueless injection' mean and why is it beneficial?

"All-in-out" sprueless injection means the system injects material directly into the cavity without a traditional runner or sprue, eliminating runner waste. Benefits include lower material loss, reduced post-processing, and cleaner production—especially valuable for expensive rubber compounds.

6. How accurate is the machine's injection metering?

The VI-AO series delivers high metering precision. The specification cites measuring precision for a 1000 cc injection volume up to ±0.1 g, and overall molding accuracy is stated as 5–10 times better than conventional injection machines.

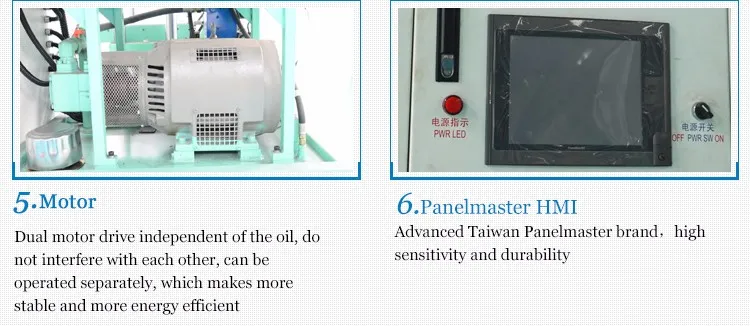

7. What energy-saving features does the machine have?

The machine uses a servo-controlled system which can save up to 40% in energy compared with conventional hydraulic-only machines by optimizing pump/motor usage and minimizing idle energy consumption.

8. What is the anti-collision molding system?

The patented anti-collision molding system prevents mold damage that can occur from misalignment or accidental collisions by detecting abnormal conditions and stopping or correcting motion to protect the mold.

9. What utilities and power requirements does the 300 Ton model need?

The 300VI-AO requires an electrical supply for drive and heaters; approximate motor drive power is 15 hp and electric heating power is around 24 kW (varies with configuration). Exact electrical specifications and phasing should be confirmed with the factory before installation.

10. What are typical cycle times and production output for shoe soles?

Cycle time depends on part size, wall thickness, material, mold design, and curing requirements. Small to medium shoe soles often range from sub-30 seconds to a few minutes. For precise production estimates, provide sample parts or part drawings so cycle time can be calculated.

11. What mold sizes and mold thicknesses does the machine support?

For the 300 Ton model the platen/operation table is 700 × 700 mm and minimum mold thickness is 100 mm. The thermo-plate distance (500–600 mm) and tie-bar spacing (820 × 395 mm) define the maximum usable mold dimensions.

12. Does the machine support proportional backpressure control?

Yes. The VI-AO series includes proportional backpressure control to improve molding consistency and material homogenization during injection.

13. What maintenance and service should be expected?

Regular maintenance includes checking hydraulic/servo systems, heaters, injection screws/plungers, mold alignment, and lubrication. The anti-collision and servo systems should be regularly inspected. Factory-recommended maintenance intervals and checks will be provided in the operation manual.

14. Is installation, commissioning, and operator training available?

Yes. Factory or authorized service teams typically provide installation and commissioning. Operator and maintenance training can be provided—confirm scope and fees with the supplier when ordering.

15. Are spare parts and technical support available?

Standard spare parts and technical support are normally available through the manufacturer or authorized distributors. It's recommended to order critical wear parts (seals, heaters, sensors) as spares and to confirm parts lead times and after-sales support agreements at purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading