B21, China Town Mall, Midrand

30 ton Vehicle Equipment with gauge with hand winch press machine hydraulic shop press

- Section : Machinery

- Category : Machine Tool Equipment

- SKU : 1600652514904-1713002983

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the rated capacity of this press?

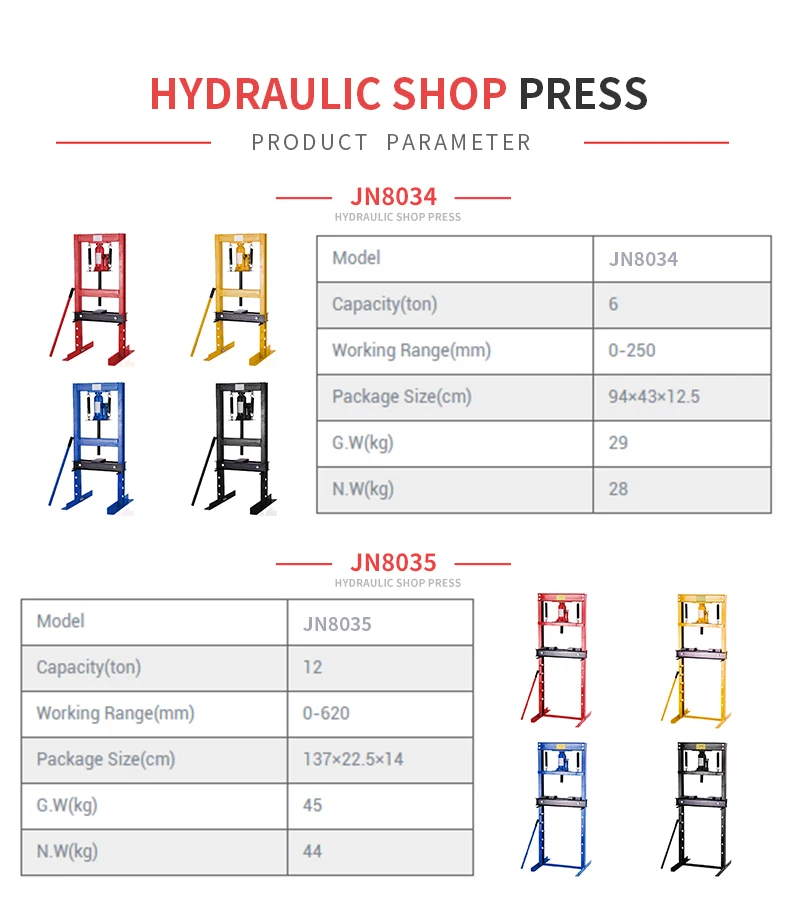

This model is rated at 20 tons (20,000 kgf). The product line also includes other capacities (6, 10, 12, 30 ton), so confirm you have the 20‑ton version when ordering.

2. What are the main specifications (stroke, height, working range, frame width, adjustable length, weight)?

According to the listing, typical specs are: stroke 230 mm, overall height ~1700 mm, working range ~1250 mm, frame width ~700 mm, adjustable length ~150 mm, and gross weight approximately 230–245 kg. Confirm exact specs with the seller for your specific model.

3. What does the gauge measure and how should I interpret it?

The gauge displays hydraulic pressure. Because the gauge shows pressure (e.g., bar/psi), consult the manufacturer's pressure-to-force chart to convert to tonnage. Never rely solely on gauge readings to exceed the rated 20‑ton capacity.

4. How do I use the hand winch on this press?

Use the hand winch to raise or lower the work table or support plate to position the workpiece. Secure or lock the table in place before applying hydraulic pressure. Do not use the winch to bear the load during pressing—use the hydraulic ram for the pressing operation.

5. How is the hydraulic press operated?

After positioning the workpiece with the winch and supports, operate the hydraulic pump (hand lever or foot pump depending on the variant) to build pressure and apply force. Use the control/release valve to lower the ram safely and to relieve pressure when finished.

6. What safety precautions should I follow when using the press?

Wear eye and hand protection, keep hands and body clear of pinch points, never exceed the 20‑ton rated capacity, use appropriate supports and tooling, ensure the workpiece is secure, inspect the press for leaks or damage before use, and release pressure slowly and in a controlled manner. Follow the manufacturer's safety instructions.

7. What routine maintenance does this hydraulic shop press require?

Regular maintenance includes checking and topping hydraulic oil, changing oil per the manufacturer schedule, inspecting seals and hoses for leaks, tightening fittings, lubricating moving parts (winch, guides), and checking gauge calibration. Perform a full inspection before heavy or critical jobs.

8. What type of hydraulic oil should I use?

Use hydraulic oil recommended by the manufacturer. If unspecified, a common choice is ISO VG32 (hydraulic oil) suitable for ambient workshop temperatures, but confirm the exact grade in the product manual or with the seller.

9. What should I do if the pump won't build pressure or the ram moves slowly?

Check the hydraulic oil level and quality, inspect for air in the system (bleed if necessary), ensure the release valve is fully closed, examine hoses and fittings for leaks, and verify seals are intact. If problems persist, contact the supplier or a qualified technician.

10. Are tooling, press plates, or adapters included with the press?

In many listings a basic pressure plate or V‑blocks may be included, but tooling and specialized dies are often optional. Confirm with the seller which accessories are included and order any additional plates, adapters, or tooling as needed.

11. Can I use this press for vehicle repair tasks (bearing removal, bushings, ball joints)?

Yes—a 20‑ton hydraulic shop press is commonly used for pressing bearings, bushings, sleeves, and some ball joints. Always verify the required force for the specific vehicle task and use appropriate fixtures and safety procedures.

12. How should the press be installed or mounted in my shop?

Place the press on a flat, level, and structurally sound floor. For permanent installation, bolt the frame to the floor or a heavy workbench if recommended by the manufacturer. Ensure adequate clearance for operation and service. Use a forklift or lifting equipment for placement due to the unit's weight.

13. What should I know about shipping and handling for this press?

This is a heavy unit (approx. 230–245 kg). It is usually shipped on a pallet/crate and may require a forklift or pallet jack for unloading. Expect freight handling charges and ensure your receiving location can accept heavy shipments.

14. Are spare parts, seals, and replacement rams available?

Yes—most manufacturers and suppliers offer spare seals, valves, pumps, and rams. Order parts using the model number and serial number. Keep a few common seals and fittings on hand to minimize downtime.

15. Does this press have certifications (CE, ISO) and is there a warranty?

Certifications and warranty terms vary by manufacturer and seller. Many exported units carry CE marking or meet ISO manufacturing standards, and some sellers provide limited warranties. Always request certification documents and the warranty policy before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading