B21, China Town Mall, Midrand

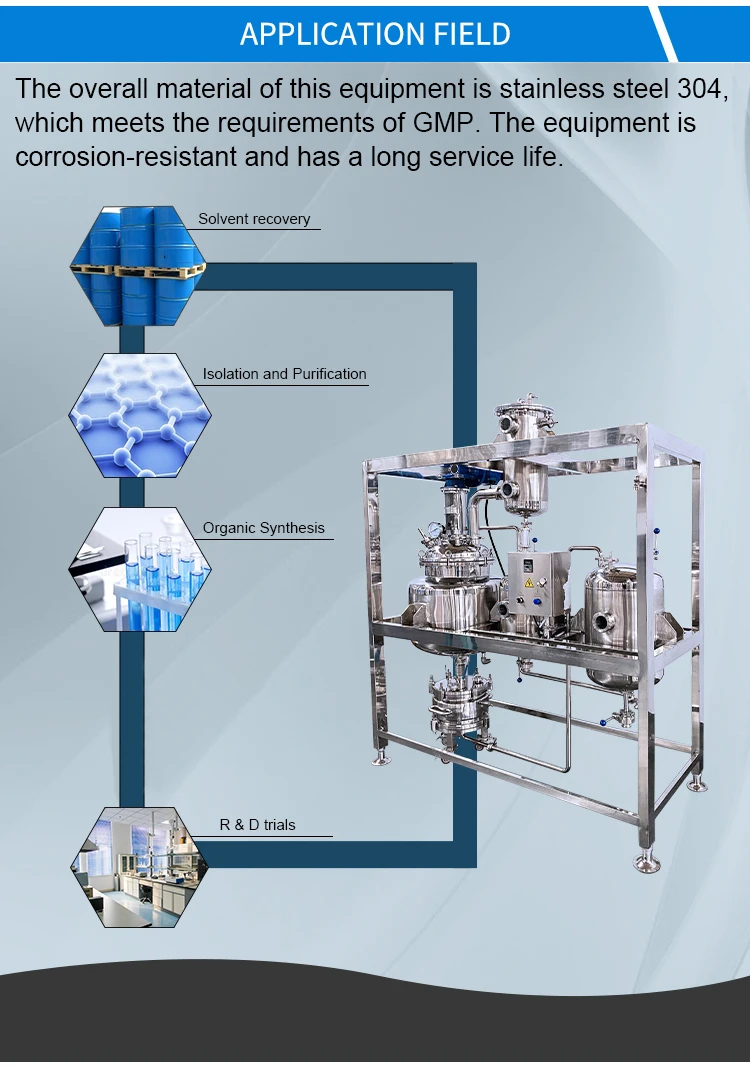

100L Chemical Methanol Crystals Lab Stainless-steel Crystallizer Reactor Equipment

- Section : Machinery

- Category : Crystallizers

- SKU : 1600493369262

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

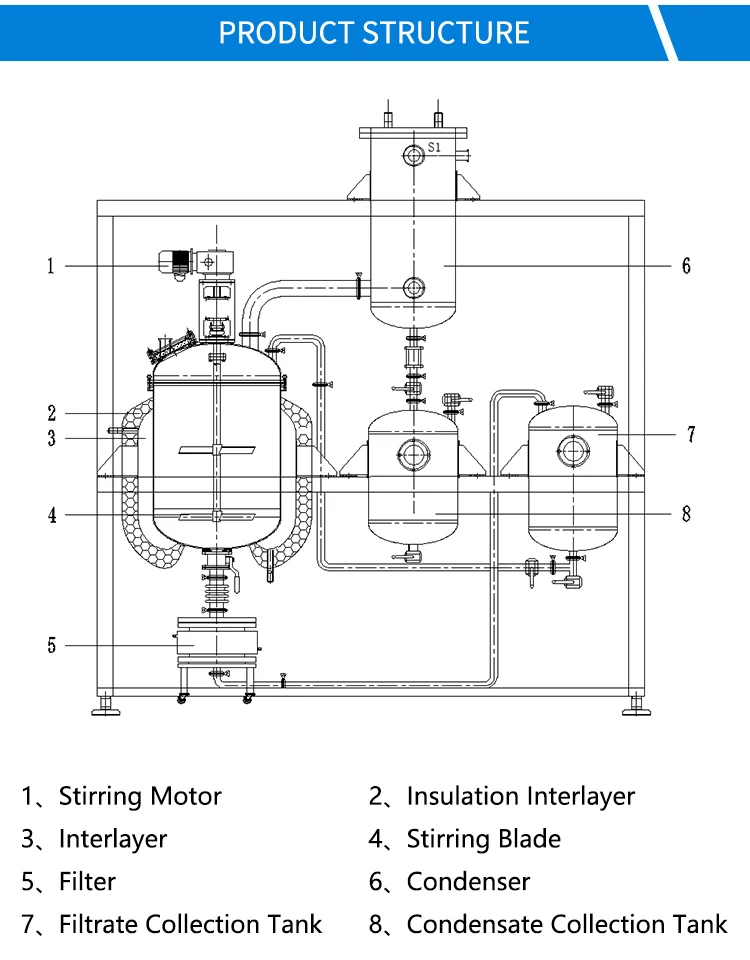

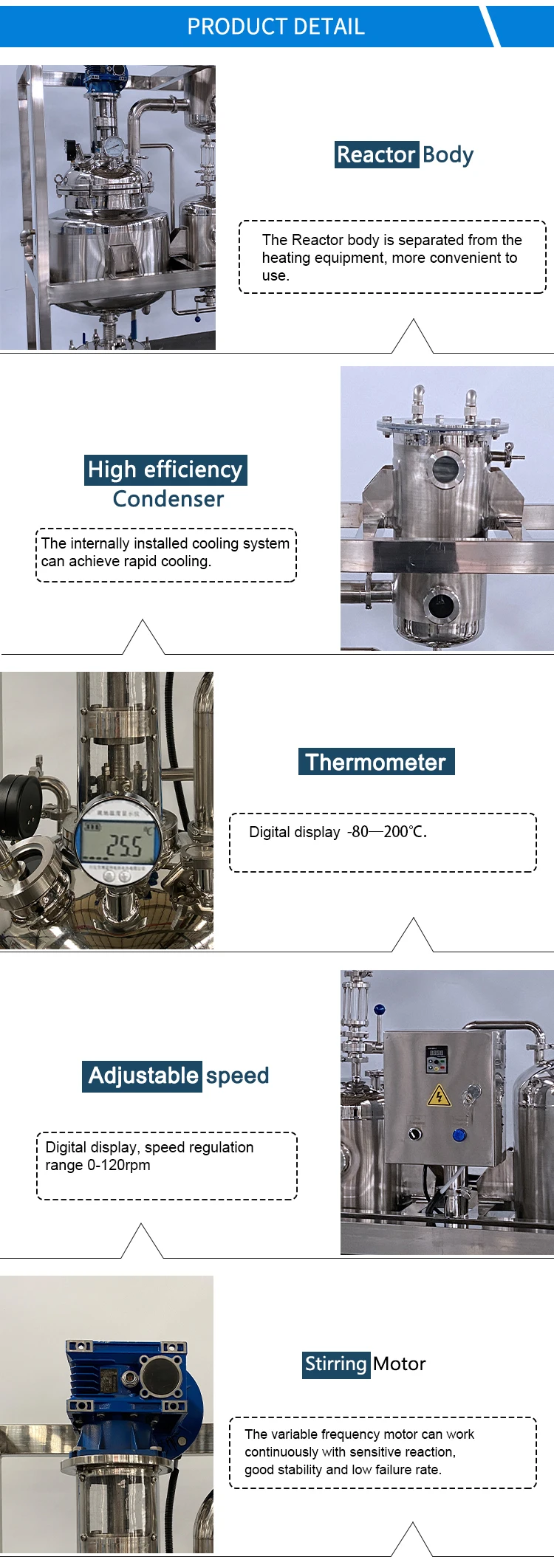

1. What materials are used in the construction of the reactor?

The reactor is constructed from SUS304 stainless steel, ensuring durability, corrosion resistance, and suitability for chemical processes.

2. What is the maximum kettle volume available for this reactor?

The reactor is available in kettle volumes ranging from 50L to 200L, allowing for various laboratory-scale crystallization experiments.

3. What temperature range can the reactor maintain during operation?

The reactor can maintain a reaction temperature range of -80°C to 250°C, providing versatility in processing conditions.

4. Does the reactor come with a collection tank?

Yes, the reactor includes a collection tank with volumes ranging from 50L to 150L to effectively collect crystallized products.

5. What is the filtration accuracy of the reactor's filtration system?

The filtration system has an accuracy range of 15-40um, ensuring efficient removal of impurities during the crystallization process.

6. How does the reactor ensure safety during high-temperature and vacuum processes?

The reactor features safety mechanisms designed to prevent overpressure and ensure stable operation under high-temperature and vacuum conditions.

7. Is the reactor easy to operate?

Yes, the reactor is designed for ease of use with automatic controls, making it user-friendly for laboratory operators.

8. What kind of after-sales support is available?

After-sales support includes video outgoing inspection, machinery test reports, and technical support for ongoing assistance.

9. Can the reactor be used for processes other than methanol crystallization?

Yes, the reactor is suitable for various sensitive chemical processes beyond methanol crystallization.

10. What is the stirring power range of the reactor?

The stirring power of the reactor ranges from 0.5kW to 1.1kW, facilitating effective mixing during the crystallization process.

11. What is the ultimate vacuum capability of the reactor?

The reactor can achieve an ultimate vacuum of -0.098Mpa, which is essential for processes requiring low-pressure environments.

12. What is the role of the thermal insulation layer?

The reactor features a 50mm thermal insulation layer on the interlayer, ensuring energy efficiency and better control over internal temperatures.

13. What are the dimensions of the discharge port from the ground?

The distance from the discharge port to the ground is between 200-300mm, facilitating easy access for collection.

14. Are there different models of this reactor available?

Yes, the reactor is available in different models, including SCR-50, SCR-100, and SCR-200, corresponding to different kettle volumes.

15. What is the stirring speed range of the reactor?

The stirring speed can be adjusted using frequency control, ranging from 0 to 120rpm for optimal mixing.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading