B21, China Town Mall, Midrand

- Products Sourcing

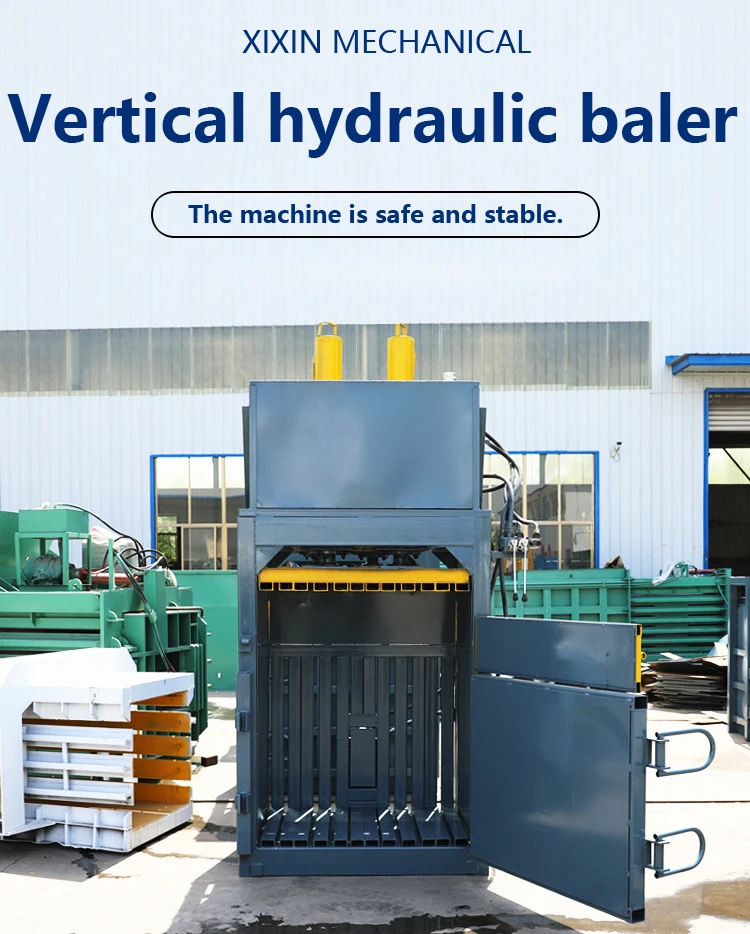

Single Cylinder Vertical Hydraulic Baler: Waste Compaction Solution for many African Industries

-

Test eman - ignore this quote

-

13 Aug 2025

-

82 Comment

Introduction

The Single Cylinder Vertical Hydraulic Baler is a game-changing piece of industrial equipment designed to streamline waste management and material compaction across Africa’s diverse industries. By efficiently compressing loose, bulky materials—such as straw, waste paper, textiles, plastics, and more—into compact, manageable bales, this machine addresses critical challenges faced by African businesses: high transportation costs, inefficient storage, and the need for sustainable, cost-effective waste-to-value solutions. For procurement managers, engineers, and SME owners seeking to boost productivity and minimize operational expenses, the Single Cylinder Vertical Hydraulic Baler delivers a high-capacity, robust, and reliable answer—available now through Afrimart, Africa’s leading B2B sourcing platform.

What Is a Single Cylinder Vertical Hydraulic Baler?

A Single Cylinder Vertical Hydraulic Baler is an industrial compaction machine that uses hydraulic pressure to compress various soft and loose materials—such as agricultural residue, plastics, textiles, and waste paper—into dense, easily-transportable bales. This baler operates with a single hydraulic cylinder mounted vertically, providing powerful downward force to compact materials in a confined chamber.

The baler's core function is to reduce the volume of waste or recyclable materials, making them more manageable for storage, transport, or resale. Operators simply load loose material into the baling chamber, initiate the hydraulic press, and the machine compresses the material into a tight, uniform bale. The end result is a compact, aesthetically pleasing package that dramatically reduces handling and logistics costs.

Technically, the baler features a rugged steel frame, a high-efficiency hydraulic pump, and an easy-to-operate control panel. Its vertical design ensures a small footprint, making it suitable for facilities with limited floor space. With models ranging from 10T to 100T in pressing force, the baler can handle everything from small textile workshops to large-scale recycling plants.

Core Applications of the Single Cylinder Vertical Hydraulic Baler

The versatility of the Single Cylinder Vertical Hydraulic Baler makes it indispensable across a wide range of African industries. Its ability to handle diverse input materials and deliver high-capacity compaction is especially valuable in the following sectors:

- Agriculture: Compressing straw, forage, cotton, wool, and other crop residues for easier storage, transport, or sale. Particularly useful for commercial farms and cooperatives looking to monetize agricultural byproducts.

- Recycling & Waste Management: Baling waste paper, cardboard, plastics, and other recyclables to optimize collection, storage, and export processes. Essential for municipal waste facilities and recycling businesses.

- Textile & Garment Manufacturing: Packing garments, fabrics, yarn, and textile offcuts into compact bales, reducing warehouse clutter and streamlining shipping logistics.

- Retail & Distribution: Managing packaging waste (e.g., boxes, plastic wrap) in supermarkets, warehouses, and distribution centers, improving workplace safety and efficiency.

- Construction & Mining: Handling loose packaging materials, sacks, or light foam used in construction, mining camps, or remote sites where waste removal is logistically challenging.

- Food Processing: Compacting sacks, woven bags, and packaging waste from food production lines, ensuring a cleaner, safer environment.

In the African context, the baler’s adaptability is crucial. For example, South African recycling firms can use it to meet growing export demands for baled recyclables, while Nigerian textile factories can streamline production by managing offcuts more effectively. Its compact design and reliable operation make it equally suitable for rural cooperatives and urban industrial parks.

Technical Specifications Table: Single Cylinder Vertical Hydraulic Baler Models

To ensure optimal performance for every application, the Single Cylinder Vertical Hydraulic Baler is available in multiple models, each tailored for specific capacity and space requirements. Below is a comparison of key models and specifications:

| Model | Motor Power (KW) | Packing Size (mm) | Oil Cylinder Inner Diameter (mm) | Oil Cylinder Outer Diameter (mm) | Pressing Force (Tons) | Input Material | Certifications |

|---|---|---|---|---|---|---|---|

| 10T Single Cylinder | 7.5 | 800 × 400 × 800 | 100 | 115 | 10 | Straw, waste paper, cotton, plastic, textiles | CE, ISO9001 |

| 20T Single Cylinder | 7.5 | 800 × 400 × 800 | 125 | 140 | 20 | Straw, waste paper, cotton, plastic, textiles | CE, ISO9001 |

| 30T Single Cylinder | 11 | 1000 × 600 × 800 | 140 | 160 | 30 | Straw, waste paper, cotton, plastic, textiles | CE, ISO9001 |

| 40T Double Cylinder | 11 | 1000 × 600 × 800 | 125 | 140 | 40 | Straw, waste paper, cotton, plastic, textiles | CE, ISO9001 |

| 60T Double Cylinder | 15 | 1200 × 800 × 1000 | 140 | 160 | 60 | Straw, waste paper, cotton, plastic, textiles | CE, ISO9001 |

| 80T Double Cylinder | 18.5 | 1200 × 800 × 1000 | 160 | 180 | 80 | Straw, waste paper, cotton, plastic, textiles | CE, ISO9001 |

| 100T Double Cylinder | 22 | 1200 × 800 × 1000 | 160 | 180 | 100 | Straw, waste paper, cotton, plastic, textiles | CE, ISO9001 |

Key Benefits of the Single Cylinder Vertical Hydraulic Baler

- Significant Cost Savings: Reduces transportation and storage costs by compressing bulky materials into high-density bales.

- Improved Productivity: Fast, automated operation streamlines waste management and material handling, freeing up labor for core activities.

- Space Optimization: Minimizes warehouse or facility clutter, enhancing safety and operational efficiency.

- Versatile Input Handling: Processes a wide range of soft, loose, and recyclable materials for maximum ROI.

- Robust, Durable Construction: Engineered for continuous use in demanding African environments, with reliable hydraulic components and steel framing.

- Simple Operation & Maintenance: User-friendly controls and straightforward design reduce downtime and training requirements.

- Sustainability & Compliance: Facilitates recycling and waste-to-value initiatives, supporting environmental compliance and circular economy goals.

- Compact Footprint: Vertical design fits in tight spaces, ideal for SMEs and facilities with limited floor area.

Why the Single Cylinder Vertical Hydraulic Baler Matters for African Industry

African businesses face unique operational challenges: unreliable power supply, high fuel and transport costs, limited waste infrastructure, and the growing pressure to adopt sustainable practices. The Single Cylinder Vertical Hydraulic Baler directly addresses these challenges:

- Reduces Reliance on Expensive Logistics: By compacting waste and recyclables on-site, companies slash the number of trips required for waste removal or material delivery, saving fuel and time.

- Supports Local Recycling Initiatives: Enables businesses to participate in the circular economy by producing standardized, high-density bales for local or export recycling markets.

- Improves Workplace Safety & Cleanliness: Keeps facilities tidy, reducing fire hazards and improving working conditions—critical for compliance and staff retention.

- Adaptable to Power Constraints: Models are available with efficient motors, minimizing energy consumption and supporting operation even in areas with unstable electricity.

- Boosts SME Competitiveness: Affordable, compact models make advanced waste management accessible to small and medium enterprises, not just large factories.

- Reduces Environmental Impact: Promotes responsible waste management, helping businesses meet regulatory requirements and improve their environmental footprint.

In South Africa, where waste management costs are rising and landfill space is limited, the baler enables businesses to take control of their waste streams. Across Nigeria, Ghana, and Kenya, it empowers agricultural cooperatives to monetize crop residue and participate in the global supply chain for recycled materials.

Where to Source the Single Cylinder Vertical Hydraulic Baler: Why Choose Afrimart?

When it comes to industrial equipment procurement in South Africa and across the continent, Afrimart stands out as the trusted B2B sourcing partner for businesses of all sizes. Here’s why procurement managers, engineers, and SME owners choose Afrimart for their baler and compaction equipment needs:

- Verified Suppliers: All equipment is sourced from thoroughly vetted manufacturers with proven track records in quality and reliability.

- Local Presence & Support: Afrimart offers on-ground assistance, from product selection and technical advice to after-sales service and warranty handling.

- End-to-End Logistics: Comprehensive logistics coordination, including customs clearance and last-mile delivery, ensures your baler arrives safely and on time.

- Secure Payments: Multiple payment options and escrow services protect your investment and streamline the procurement process.

- Tailored Solutions: Whether you need a single unit or a fleet of balers, Afrimart can customize procurement packages to fit your scale and budget.

- Warranty & Spare Parts: All machines come with manufacturer-backed warranties and ready access to spare parts and technical support.

- Expert Consultation: Afrimart’s team of industrial procurement specialists help you choose the right model for your application and site conditions.

For reliable hydraulic pump procurement, briquette press South Africa, or any other industrial compaction equipment, Afrimart is your one-stop platform for productivity, cost-efficiency, and peace of mind.

Conclusion

The Single Cylinder Vertical Hydraulic Baler is an essential investment for any African business seeking to turn waste into value, optimize operational efficiency, and meet the demands of modern industry. Its robust design, versatile application, and cost-saving benefits make it the go-to solution for agriculture, recycling, manufacturing, and more.

Sourcing your baler through Afrimart ensures you receive a genuine, high-quality product backed by expert support, secure transactions, and seamless logistics. Join the growing community of African enterprises transforming their waste management and material handling with Afrimart’s trusted solutions.

Frequently Asked Questions (FAQ)

What materials can the Single Cylinder Vertical Hydraulic Baler process?

The baler can handle a wide range of soft and loose materials, including straw, forage, waste paper, cardboard, cotton, wool, textiles, plastic packaging, woven bags, light foam, and more.

What is the difference between single and double cylinder models?

Single cylinder models use one hydraulic piston for compaction, offering a smaller footprint and lower cost, ideal for medium-capacity needs. Double cylinder models provide higher pressing force and are suitable for larger volumes or tougher materials.

How does the baler improve cost efficiency?

By compressing bulky materials into compact bales, the baler reduces transportation, storage, and handling costs, while enabling businesses to monetize recyclable waste and minimize landfill fees.

Is the baler easy to operate and maintain?

Yes. It features simple controls, robust construction, and minimal maintenance requirements, making it suitable for operators with varying skill levels.

Why should I buy from Afrimart?

Afrimart offers vetted suppliers, secure transactions, local support, warranty handling, and expert consultation, ensuring a smooth and reliable procurement experience for all industrial equipment needs in Africa.

Can Afrimart assist with logistics and installation?

Yes. Afrimart provides end-to-end logistics, customs clearance, and can arrange for installation and technical support as needed.

What certifications does the baler have?

All models come with CE and ISO9001 certifications, ensuring compliance with international quality and safety standards.

How do I request a quote or more information?

Visit Afrimart’s product page or contact our procurement specialists for a tailored quote and expert advice.

Leave Comment

Your email address will not be published. Required fields are marked

Comments

30 Jan, 2022

Glenn Greer

"This proposal is a win-win situation which will cause a stellar paradigm shift, and produce a multi-fold increase in deliverables a better understanding"